Advanced High Torque Hollow Shaft Direct Drive System

This document discusses a novel direct drive system that leverages the principles of magnetic flux, similar to those found in wind turbine generators. This rotary stage hollow shaft motor is characterized by its superior torque output within a compact design space. Numerically speaking, this equates to a two to three times increase in torque given the same design volume, when compared to traditional direct drive systems.

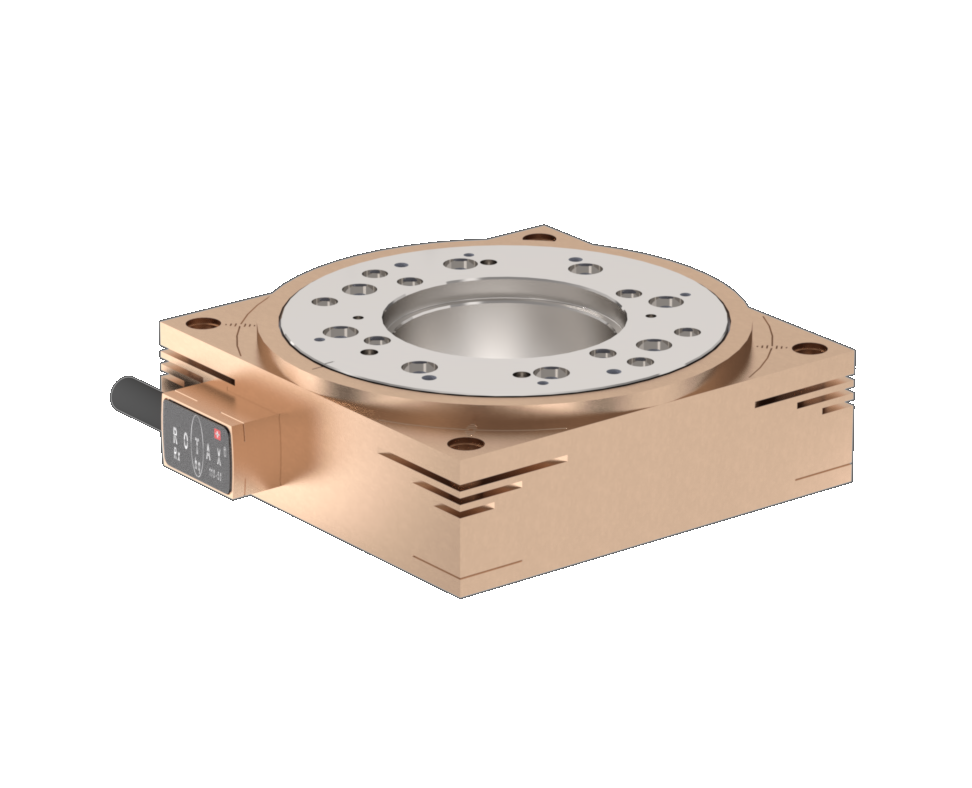

The unique design includes a continuous hollow shaft with a diameter of 50mm. This hollow design provides ample room for a variety of components such as cables, vacuum or compressed air lines, light and laser beams, optical fibres or lenses for imaging systems.

A built-in absolute measurement system ensures the device can start operation without needing prior referencing. This system provides a resolution of 2’592’000 increments per revolution, and boasts a resolution of 0.5 arcs. The design also offers the flexibility of a single-cable connection with either right-hand or left-hand output configuration.

One of the key features of this rotary stage hollow shaft direct drive system is the patented “Torque calibration” functionality. This feature allows for easy compensation of undesired cogging, and friction forces within the iron core direct drive. It further allows the specification, limitation, and monitoring of torques during operational processes. Paired with a base technology included in the system’s servo controller, it enables the recording of complete torque/angle diagrams. This eliminates the need for an additional torque sensor, making the system more streamlined and efficient.